- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Electric Built In Blinds Louver Aluminum Sliding Window

You can purchase Electric Built In Blinds Louver Aluminum Sliding Window from LEASKY with confidence, as we are a proficient producer of high-quality Electric Built In Blinds Louver Aluminum Sliding Window. We promise to provide you with the best after-sale service and prompt delivery.

Send Inquiry

Electric Built In Blinds Louver Aluminum Sliding Window is a window shading device that controls the opening and closing of the shutter blades and the angle adjustment through motor drive. It is mainly composed of motor, control system, shutter blades, window frame and other parts. The motor is the core power source, and drives the shutter blades to rotate under the command of the control system. The control system can be operated by a remote control, a wall switch or an intelligent control system.

The window usually consists of the following main parts:

1. Shutters: The shutters built into the insulating glass can be adjusted by electric control to achieve the functions of lighting and shading. The shutters are controlled by magnetic force and can be flipped and adjusted at any angle to achieve the effect of full light transmission, semi-light transmission or light blocking.

2. Shutters are usually made of aluminum alloy, which has the following advantages:

1. Corrosion resistance: Aluminum alloy has good corrosion resistance and can remain stable in various environments.

2. Lightweight: Aluminum alloy materials are light and easy to install and maintain.

3. High strength: Aluminum alloy has high strength and can withstand large external forces.

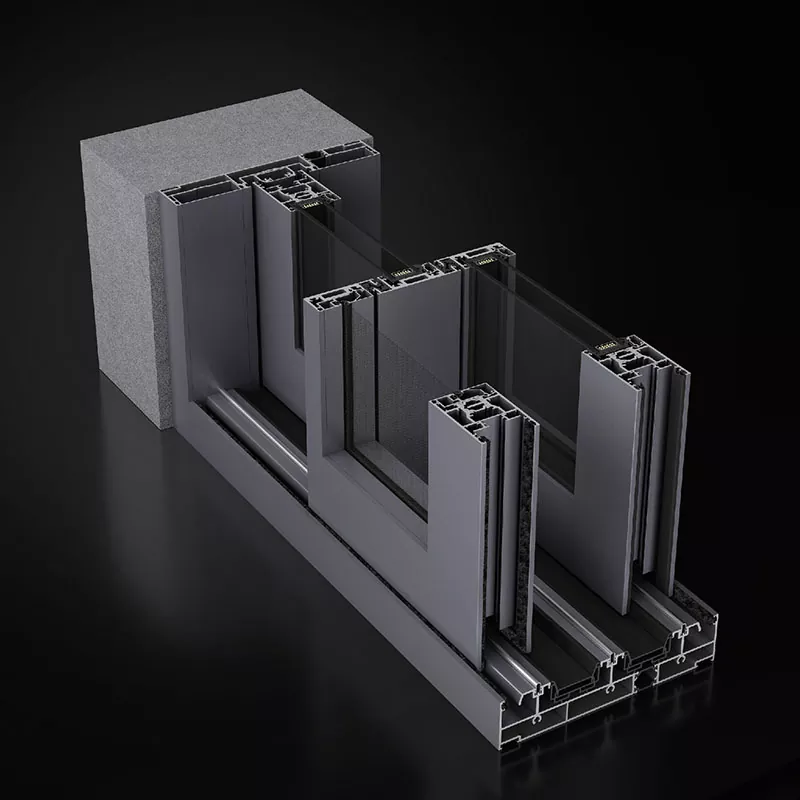

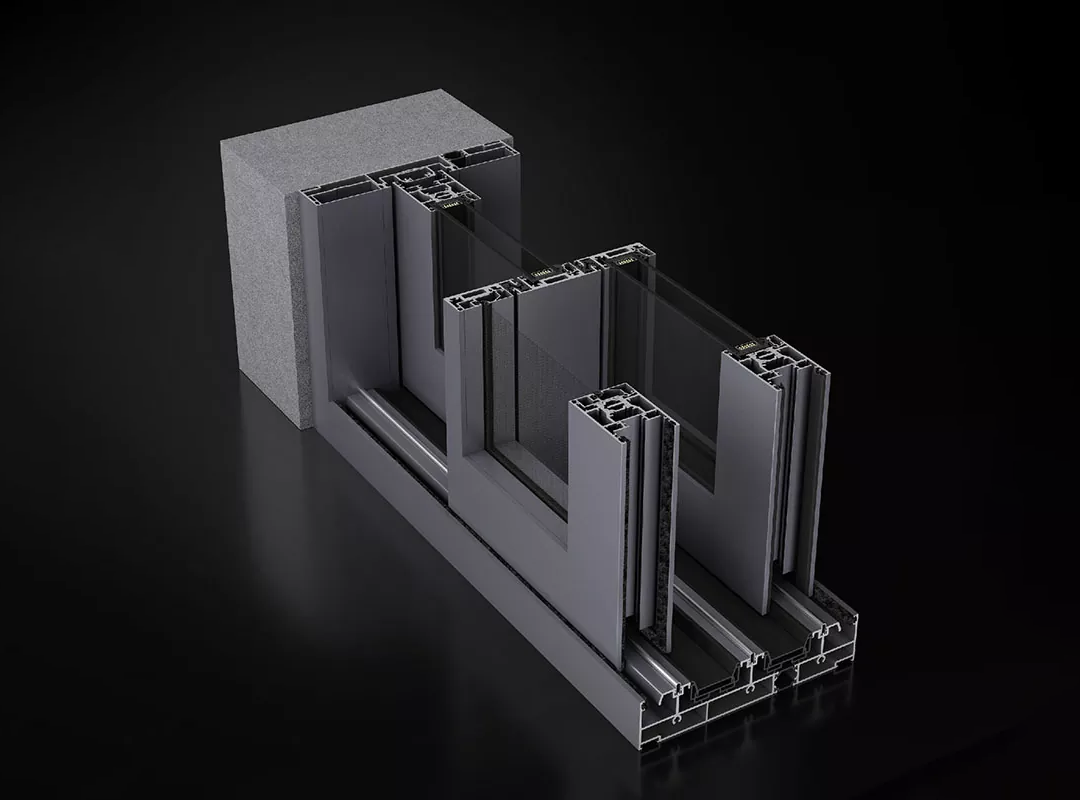

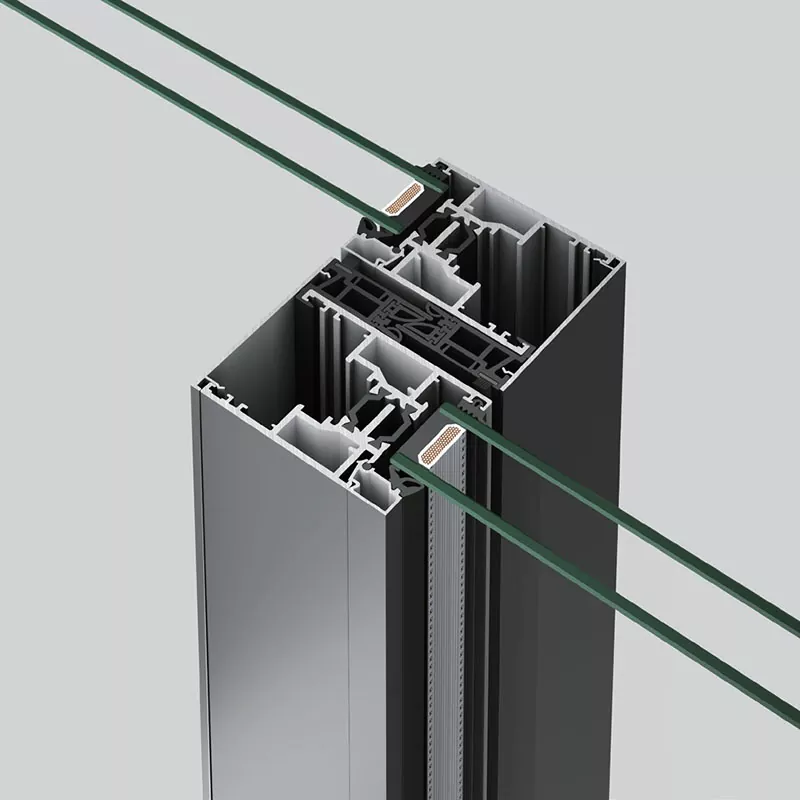

3. Aluminum sliding window structure: Electric sliding windows use electric control to push and pull the windows. Its basic structure includes pulleys, transmission parts, locking devices, sealing strips, hinges and guide rails. The pulleys are made of high-strength wear-resistant materials, and there are many types of transmission parts to choose from, such as gear rack type, wire rope type, etc. The locking device is used to fix the glass and ensure the tightness of the window, and the sealing strip is used to prevent rainwater from seeping in and prevent dust from entering.

Broken bridge lift and sliding door of depth 150mm

Product configuration

The thickness of profile: main wall thickness 3mm

The thickness of door frame: 150mm

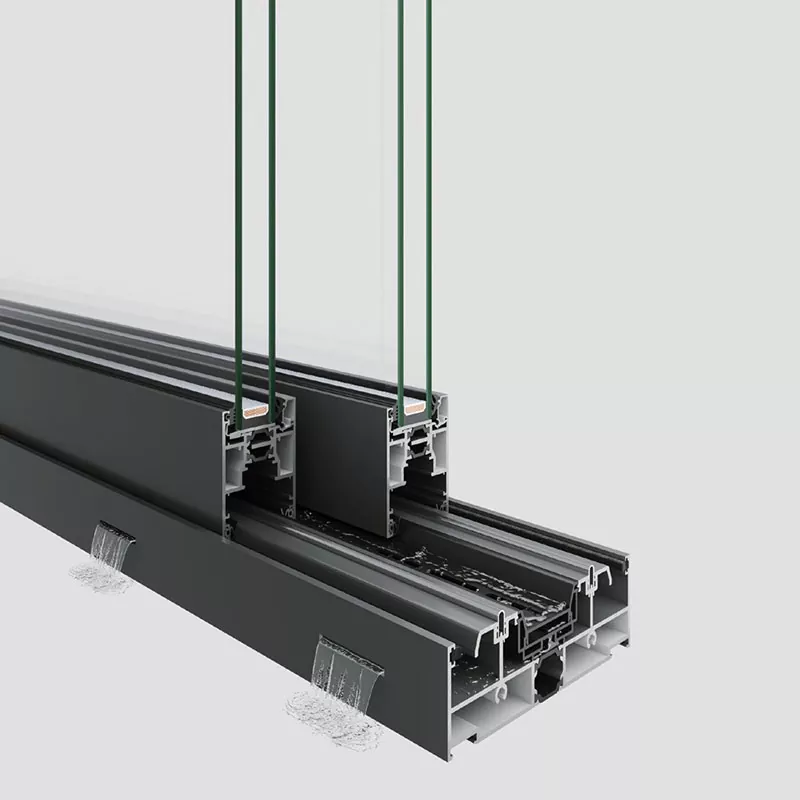

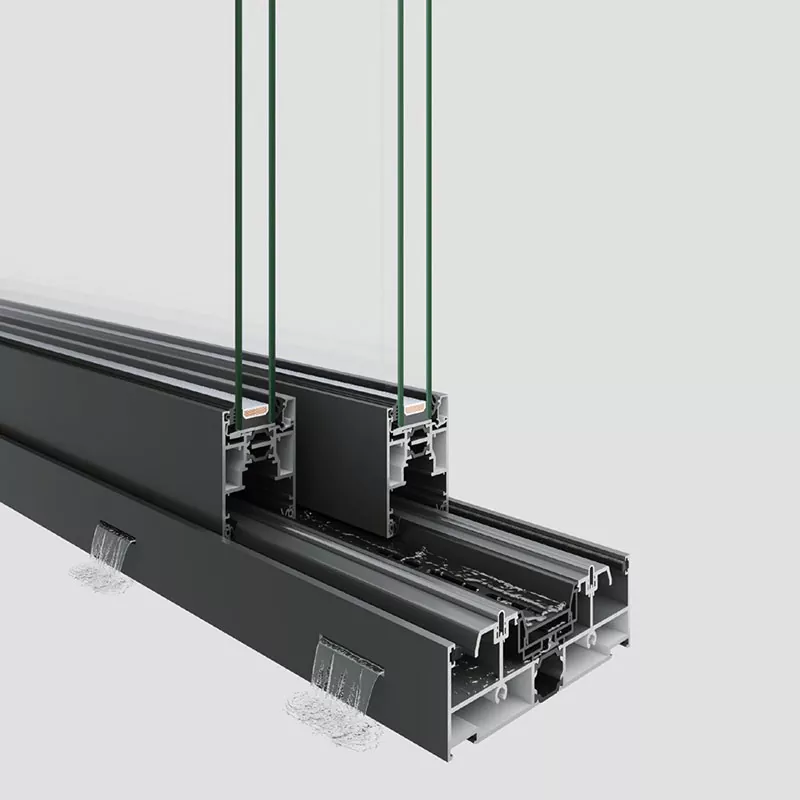

Opening method: lifting and sliding Drainage method: integrated drainage

Hardware configuration: Gewu

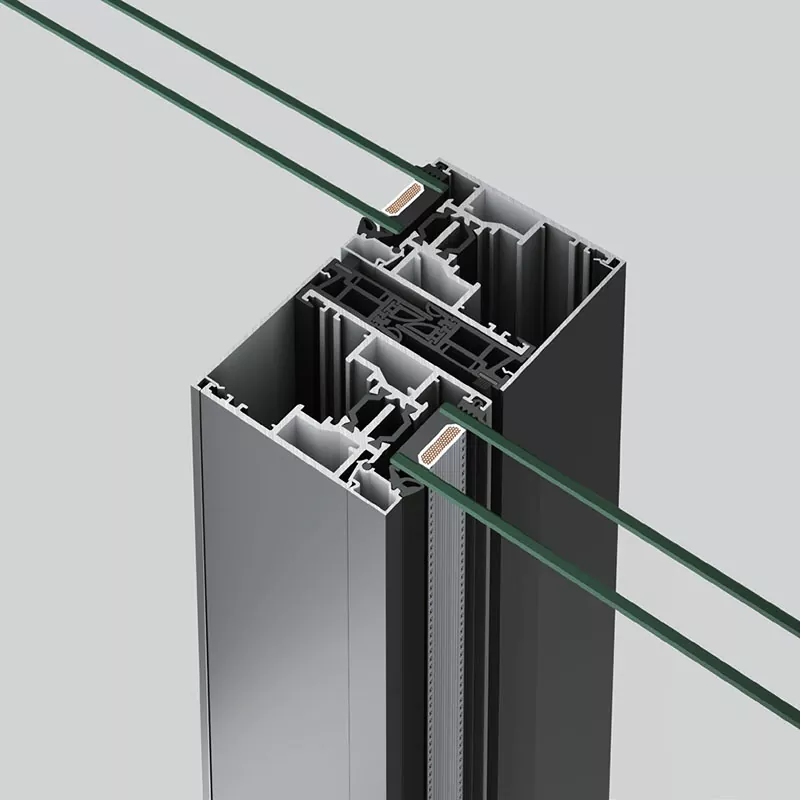

Insulation strip: Ronghai PA66 nylon insulation strip

Glass configuration: 5+20A+5, 5+27A+5

Sealing strip: Ruiyide Sealing

Layer: 6 layers

Optional screen window: diamond mesh

Other options: two-tracks, three-tracks with screen, fixed fan of high-track and low-track broken bridge module, corner door, window door with guardrail, electric sliding door, etc. can all be realized.

Product Features

1. 6 seals, multiple isolation, nylon hook edge profiles and double-layer composite strips are interlocked,and the thermal insulation performance and sealing treatment would be more perfect.

2. The integrated drainage track is adjusted layer by layer, the drainage is smooth,the continuous double-layer filter cover effectively prevents backflow, and the drainage holes enhance the watertight performance.

3. The embedded frame-wrapped fan structure, multiple strips are tightly attached to the fan frame to form a highly sealed overlapping state, which not only ensures sealing but also ensure the anti-pry function.

4. High-load-bearing pulley module, allowing a single fan weight of up to 500KG, a single fan size of up to 3.5MX3.2M,the maximum opening width, enjoy unlimited vision, a large field of view and a large pattern, more suitable for large living room space applications.

5. High-strength design of integrated corner code, stable connection, corner group and T connection are all seamlessly connected with glue-injected corner code to ensure frame strength and surface flatness.

Broken bridge lift and sliding door of depth 150mm

Six-Layers sealing, multiple isolation

Nylon hook edge profiles and multi-layer composite strips are interlocked, and the thermal insulation performance and sealing treatment are more perfect.

Integrated drainage track

Layer-by-layer filtration, smooth drainage, continuous double-layer filtration, effectively prevent overflow, and the drainage holes set have strong water tightness.

High load-bearing design

The high load-bearing sliding module allows a single leaf weight of 500KG, a single leaf size of 3.5MX3.2M, and a maximum opening width, enjoying unlimited comfort.